INSET is a rapidly growing company founded in

2017 and reorganised in 2020.

The main priorities in our cooperation with the

clients

are efficiency, quality and customer satisfaction.

The experience gained by each and every specialist

throughout many years of

work in the OFFSHORE, ONSHORE as well as

MARITIME and

SHIPYARD INDUSTRY projects has enabled us to

apply technical solutions which are highly acclaimed by our

regular customers.

Managers, team leaders and

technicians always perform their work

in compliance with the

DNVGL, BV, TUV RHEINLAND, PRS and

RINA Standards.

We provide technical services worldwide. Our

highly qualified technicians may are capable of

reaching your project’s location within 48 hours

following your order.

Our policy is based on the principles of Health and

Safety

along with Quality, which hold an equal status with all the other

main business objectives.

INSET Company strives to conduct its projects in

such a manner as to

eliminate any harm to the personnel, third

parties or damage to the facilities.

Commencing cooperation with us you will prove beneficial to you

due to our commitment to quality throughout the entirety of the

project’s process.

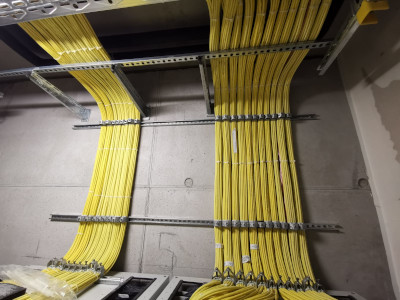

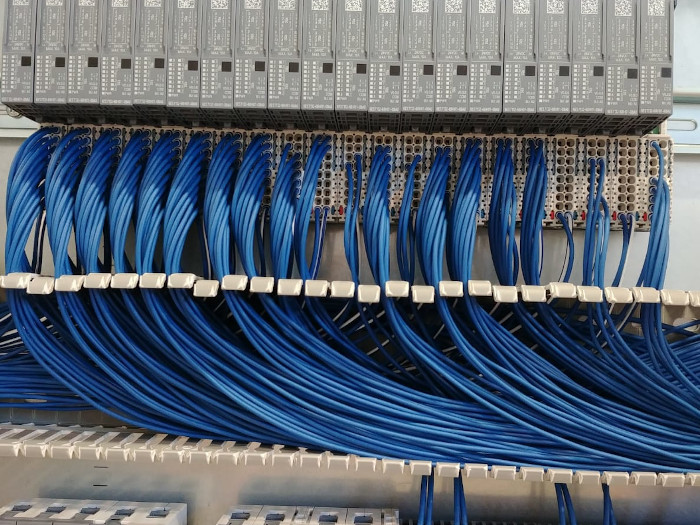

NEW ELECTRICAL INSTALLATION

Based on experienced team leaders and technicians INSET company is able to make new installation at Industrial Objects and Ships.

- Cable laying

- Cable trays installation

- Cable termination

- Mark cable system

- Cable installation to devices

- System commissioning

We share our experience and knowledge. We collaborate with each other and our customers, and we continue to grow and develop as a result.

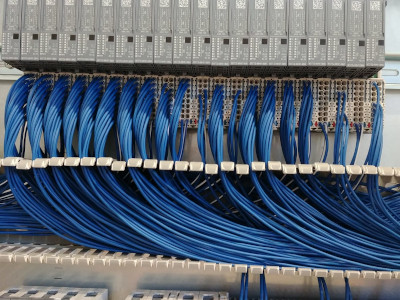

RENEWAL ELECTRICAL INSTALLATION

The repair or renewal of an existing installation on industrial facilities or ships is a frequent inquiry from our customers.

We are able to generate and adapt to the existing systems while maintaining their work standards. The main advantage is the ability to select subassemblies and cables to the extant elements of the electrical installation in compliance with the classification societies.

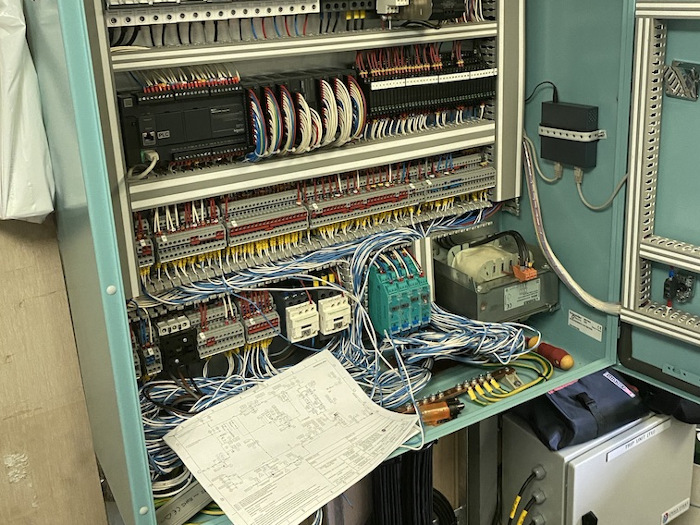

Electrical Cabinets Prefabrication

The ability to optimize time in prefabricating switchboards is the main domain of our technicians. The experience gained during many years of contracts with regular clients allowed us to perform the work in accordance with the agreed quality of work. Electrical ethics and standards are crucial aspects in the prefabrication of electrical cabinets for sectors such as: power plants, server rooms, ship’s engine room, main switchboards, auxiliary boxes.

Mechanical fitting

Conveyors / switchboards / cable trays / industrial facilities

Conveyors are frequent elements of sorting parcels, mail, production, and warehouses. We are experienced in technical assistance during assembly and installation of roller, belt and bucket conveyors.

Mechanical installation of main switchboards and auxiliary boards is performed in accordance with the documentation prior to the installation of electrical devices and after tests (disassembly in the workshop, transport to the installation site and reassembly - industrial facilities and ships). We are knowledgeable about safety and security during transport.

Cable trays are usually the first component prior to installing cables. Therefore, they must be made according to the designer's intention and the realities on site. Quick and effective installation allows to fit into the plan of the entire project chain. Our mechanics are certified to weld using the 135/136/141/111 method. Fitting works are performed under control.

Installation of industrial structures, i.e. industrial robots, steel structures, conveyors, elevators, platforms, stairs, ladders, etc.

Shipyard works

The implementation of electrical installations requires a lot of

experience, especially when participating in the entire project’s

process.

Our team constantly participates in ship repairs and new

construction projects. We mainly specialize in the expansion of

power supply systems,

reconstruction of main switchboards, parallel operation of auxiliary

engines, installation of new power supply and control systems.

INDUSTRIAL WORKS

INSET technicians perform electrical and assembly work on industrial facilities.

The work includes:

- installation of conveyors,

- industrial machinery,

- construction elements,

- construction of cable routes,

- electrical installations,

- construction of switchboards.

We participate in a process of maintenance. We are experienced in working on projects for DHL, AMAZON, EDEKA, SPARR, FedEX, and international airports.

WORKSHOP WORKS

We are able to repair the device for you or simply make a new one on components.

We prefabricate switchboards and rewind electric motors.

What is more, we carry out inspections of devices with a guarantee.

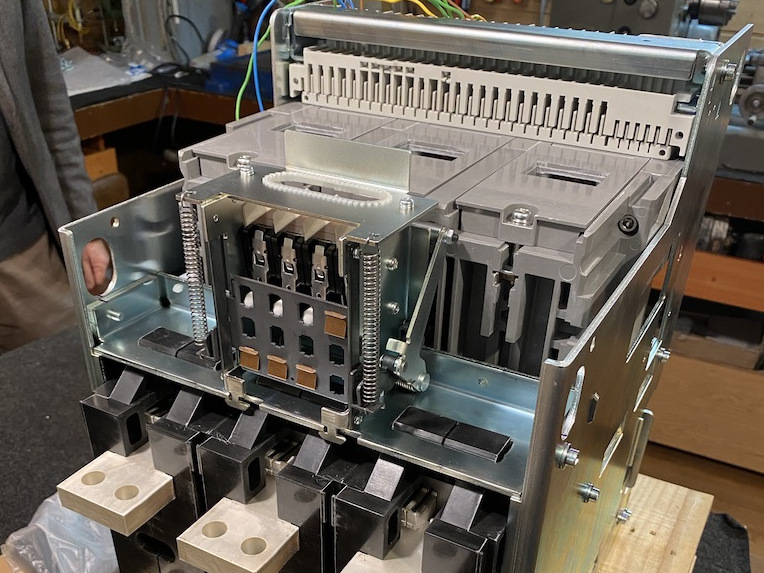

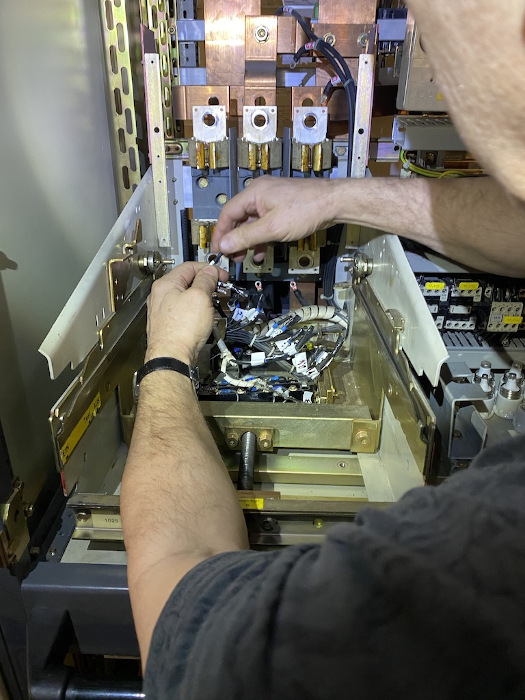

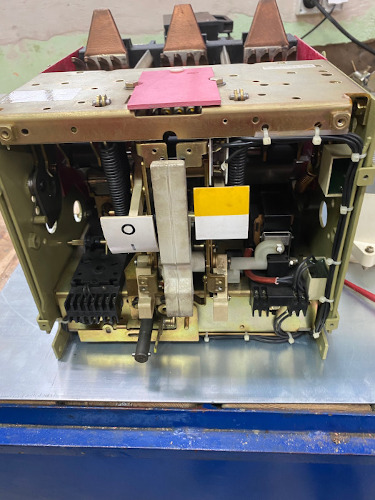

ELECTRICAL DEVICES OVERHAULING

We perform the inspections and

maintenance of circuit breakers. The next step is

to test under load and

work with a current protection.

We issue a certificate for

everything with the test report. All the work is

performed under the supervision of our

experienced team in laboratory conditions.

PROJECT MANAGEMENT

We manage electrical projects from the moment of planning through

the selection of materials and execution to the implementation and

commissioning.

Site managers are experienced and certified by a diploma staff

with the necessary qualifications to perform this task

Measurements

Thermovision measurements on ships, oil rigs and industrial facilities. We have necessary equipment from FILAR with calibration certification. We perform a full measurement with a graphic report, description and recommendations.

Measurement of insulation resistance on ships and industrial facilities.

Illuminance measurement.

CCTV INSTALLATION

Comprehensive CCTV installations along with the selection of the manufacturer, materials and customer needs.

We plan and implement installations on industrial facilities and ships.

Real-time connection possible.

HIGHLY QUALIFIED

We focus on experience.

Our staff, technicians and subcontractors have certificates and training that allow them to perform work in accordance with the standards and quality.

INSET company is certified by DNV-GL in ISO 9001: 2015 DNV-GL

Technical Department

Karol Dopierała

Mob. +48-517-175-555

Email:

karol.dopierala@in-set.eu

INSET sp. z o.o.

Street Jana Soltana 1

72-602 Świnoujście

POLAND

Office

www.in-set.eu

Mob. +48-664-457-784

Email: office@in-set.eu